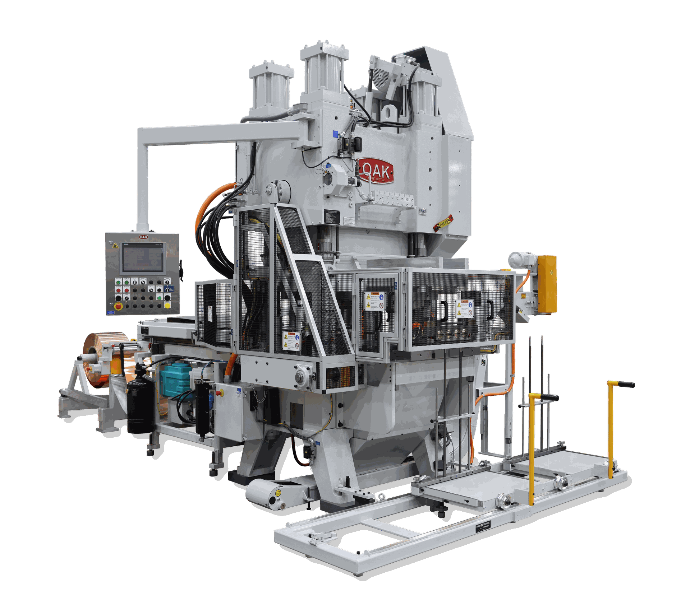

FP-2B Fin Press

Flexible, High Quality Production at a Mid-Range Price.

The OAK FP–2B fin production line serves as an ideal fin making solution when intricate fin patterns are required. Rated at 60 tons (534kN), the straight side press and supporting line equipment deliver the fin stock to the press, where it is lubricated, stamped and the final product is efficiently collected.

Machine Facts

PRODUCTION

-

160 to 300 SPM*

160 to 300 SPM*

FOOTPRINT

-

3.7 m x 10.1 m (12' x 33')

3.7 m x 10.1 m (12' x 33')

WEIGHT

-

~ 7,600 kg (16,755 lbs)

~ 7,600 kg (16,755 lbs)

AIR SUPPLY

-

60 ft3/min at 85 psi

(1.7 m3/min at 5.51 bar)

60 ft3/min at 85 psi

(1.7 m3/min at 5.51 bar)

POWER SUPPLY

-

29 kW @ .80/.82 PF, 24 VDC Controls

Foundation information supplied upon request

29 kW @ .80/.82 PF, 24 VDC Controls

Foundation information supplied upon request

TONNAGE

60 US Tons (534 kN)

FIN LENGTH

Up to 108" (2,742 mm)

FIN WIDTH

36" Press: Up to 19" (480 mm)

48" Press: Up to 31" (785 mm)

SHUT HEIGHT

9" (229 mm) - 13" (330 mm)

STROKE

1" (25 mm) - 2" (51 mm)

Advantages

Economic

-

60 ton press produces midlevel production volumes.

-

Flexible production capabilities.

-

Can accommodate various die designs.

Technical

-

Hydraulic withdrawal feature allows routine maintenance without removing the die from the press.

-

Programmable Logic Controller (PLC) stops fin production automatically when a predetermined number of fins have been stacked.

-

Damage-free fin collection system.

-

Faster die removal than the competition.

User

-

Can be modified to allow a maximum stroke length of 3" (76 mm) if necessary.

-

Program the fin length form the touch screen control panel.

-

Operator touch screen controls can be configured for different languages.

Materials & Media

Capital Sales

To request a quote or learn more about BOTI FP-2B Fin Press visit our capital sales page.