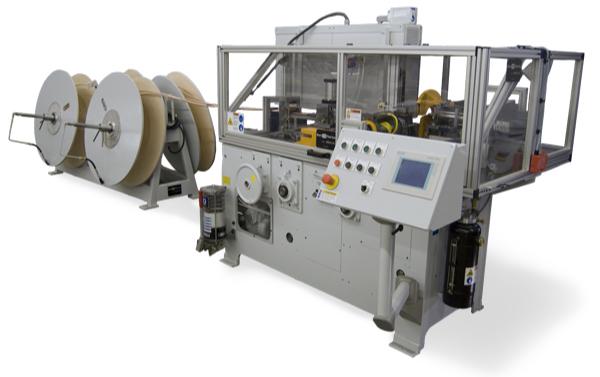

Mechanical Return Bender

Return Bends at High Production Speeds.

OAK small bending machines turn out multiple bend angles easily and dependably. The cuts are straight and bend centers are accurate, protecting your investment in the quality of your final product.

This machine is specifically designed to produce return bends at high production speeds. This machine automatically feeds, bends, and cuts off return bends using an electric motor drive with cam operated mechanisms. The Mechanical Return Bender has no hydraulics and requires only electrical and pneumatic connections.

Machine Facts

PRODUCTION

-

Up to 18 cycles per minute

Up to 18 cycles per minute

Bends per Cycle:

-

5 mm tubing: 4-6

6mm – ¼" tubing: 4 – 6

7 mm – 10mm tubing: 4 – 5

12 mm – ½" tubing: 3 – 4

?" tubing: 3

3¾" tubing: 2

5 mm tubing: 4-6

6mm – ¼" tubing: 4 – 6

7 mm – 10mm tubing: 4 – 5

12 mm – ½" tubing: 3 – 4

?" tubing: 3

3¾" tubing: 2

FOOTPRINT

-

6.08’ x 4.92’ x 5.91’

(4.9 m x 1.5 m x 1.8 m)

6.08’ x 4.92’ x 5.91’

(4.9 m x 1.5 m x 1.8 m)

WEIGHT

-

~ 10,000 lbs (4,536 kg)

~ 10,000 lbs (4,536 kg)

AIR SUPPLY

-

10 ft3/min at 80 psi

(0.3 m3/min at 5.5 bar)

10 ft3/min at 80 psi

(0.3 m3/min at 5.5 bar)

POWER

-

9 kW @ .80/.82 PF, 24 VDC Controls

**Foundation information supplied upon request

9 kW @ .80/.82 PF, 24 VDC Controls

**Foundation information supplied upon request

SIZE

5mm – ¾” OD

Straight lengths or coil tubing

MATERIAL

Copper or Aluminum

Advantages

Economic

-

Point-of-use production of return bends enhances lean manufacturing processes.

-

In-house production eliminates the shipping and handling costs of out-sourced material.

-

Allows better control of raw material prices through the use of existing procurement contracts.

Technical

-

Can be configured to produce bends from a variety of materials.

- Various uncoiled designs allow the use of the most cost effective tubing coil configuration.

User

-

Touchscreen Human Machine Interface (HMI) facilitates easy access to various operator controls and eliminates the need for manually adjusted hard stops.

-

Guard design allows an unobstructed view of the tooling and working parts while ensuring the safety of the operator.

-

Guarding is electronically locked during machine operation to ensure operator safety.

-

Operator touch screen controls can be configured for different languages.

Materials & Media

Capital Sales

To request a quote or learn more about BOTI's Mechanical Return Bender visit our capital sales page.